Advancements in Materials Science for Industry

Materials science, a field at the intersection of physics, chemistry, and engineering, is continuously evolving, driving significant transformations across various industrial sectors. Its ongoing advancements are pivotal in shaping the future of manufacturing, enhancing product performance, and fostering sustainable practices. From aerospace to consumer electronics, the development of novel materials with superior properties enables the creation of more efficient, durable, and environmentally friendly products and processes, influencing global economies and trade dynamics. These innovations are fundamental to modern industrial progress and technological innovation, impacting everything from production efficiency to the overall enterprise strategy.

Materials Science and Modern Manufacturing

Modern manufacturing processes are heavily reliant on the continuous evolution of materials science. The development of new alloys, composites, and polymers with enhanced strength-to-weight ratios, improved thermal resistance, or superior electrical conductivity directly impacts the capabilities and efficiency of industrial production. These advancements enable manufacturers to create components that are lighter, stronger, and more durable, leading to improved product performance and reduced operational costs. The integration of advanced materials often goes hand-in-hand with automation, allowing for precision fabrication and assembly that would be impossible with traditional materials.

Enhancing Supply Chain Operations with Advanced Materials

The impact of materials science extends significantly into supply chain operations and logistics. Materials with extended lifespans, reduced weight, or improved resistance to environmental factors can streamline global supply networks. For instance, lighter packaging materials reduce shipping costs and fuel consumption, contributing to both economic efficiency and sustainability. Furthermore, materials designed for specific applications, such as high-performance sensors for real-time monitoring, can enhance the visibility and traceability within the supply chain, optimizing overall operations and reducing waste. This directly contributes to more robust and responsive enterprise strategies.

The Role of Innovation in Materials Development

Innovation is at the core of materials development, driving the creation of entirely new classes of substances with unprecedented properties. Research and development efforts are constantly exploring novel structures at the atomic and molecular levels, leading to breakthroughs in areas like nanotechnology and smart materials. These innovations are not just about improving existing products but about enabling entirely new technologies and markets. The continuous cycle of research, development, and application is crucial for maintaining a competitive edge in the global economy and for addressing complex challenges across various industries.

Sustainability and the Future of Industrial Materials

Sustainability has become a central focus in materials science, with a growing emphasis on developing materials that minimize environmental impact throughout their lifecycle. This includes the creation of biodegradable polymers, recyclable metals, and materials derived from renewable resources. The drive for greater efficiency and reduced waste in production processes is also a key aspect, contributing to a circular economy model. These efforts are vital for addressing global environmental concerns and for establishing long-term, responsible industrial practices that align with broader sustainability goals.

Digitalization and Analytics in Materials Research

Digitalization and data analytics are revolutionizing the field of materials science, accelerating the pace of discovery and development. Computational materials science uses advanced algorithms and simulations to predict material properties and behaviors, reducing the need for extensive physical experimentation. Big data analytics can process vast amounts of experimental data, identifying patterns and insights that guide further research. This digital transformation enhances the efficiency of materials development, from initial concept to industrial production, and informs strategic decisions for future material applications. The integration of technology in this area is critical for future innovation.

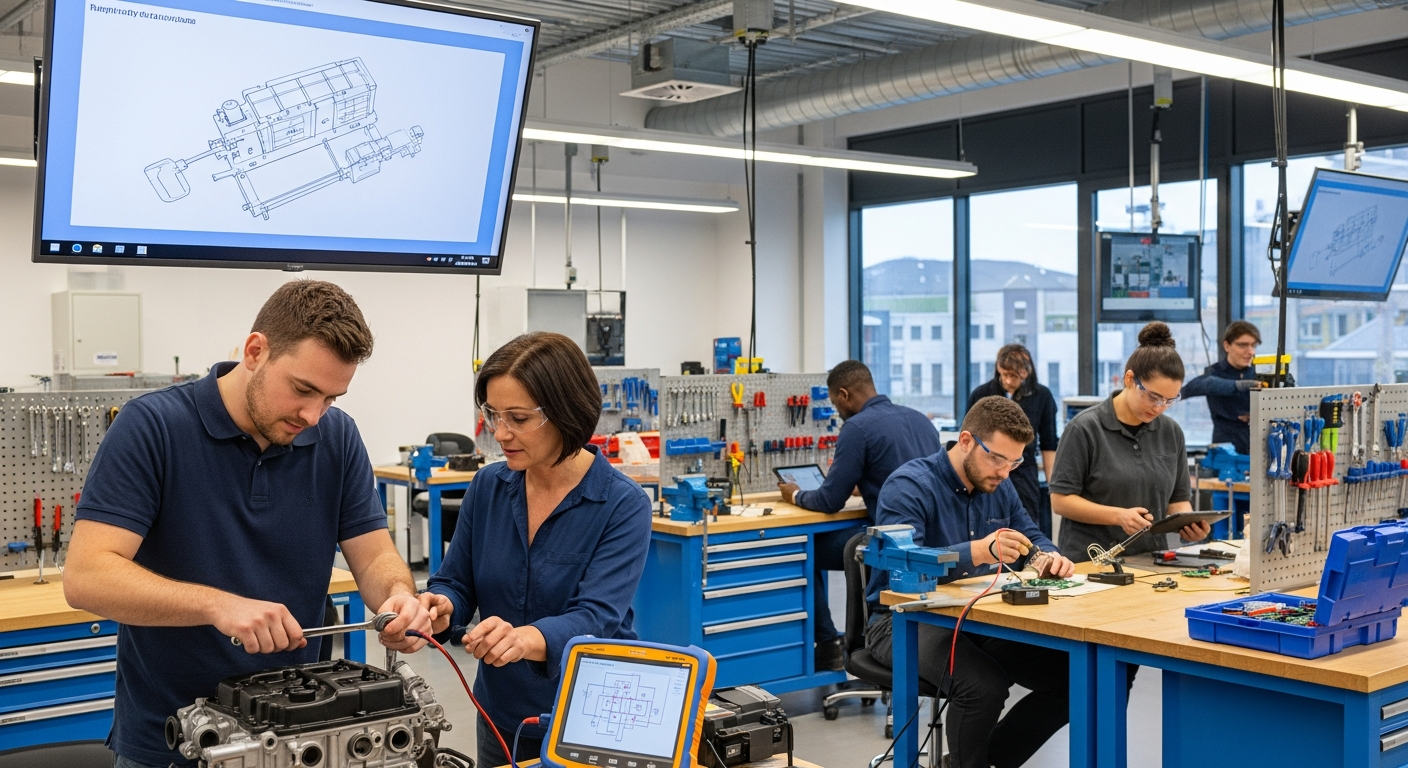

Workforce Adaptation and Strategic Planning for New Materials

As new materials emerge and manufacturing processes evolve, there is a corresponding need for workforce adaptation and strategic planning. Industrial enterprises must invest in training and upskilling their workforce to handle advanced materials and the sophisticated technologies used in their production and application. This includes expertise in areas like advanced manufacturing techniques, quality control for novel materials, and data analytics for process optimization. A proactive strategy for workforce development ensures that organizations can effectively leverage materials science advancements to maintain operational excellence and drive market growth.

Advancements in materials science are fundamentally reshaping the industrial landscape, offering solutions to complex challenges in manufacturing, supply chain management, and sustainability. The ongoing interplay between innovation, technology, and strategic development ensures that industries can continue to evolve, creating more efficient, environmentally responsible, and technologically advanced products and processes for a global market. This continuous evolution underscores the critical role of materials science in driving economic progress and shaping the future of enterprise.