Digital Transformation Across Industrial Verticals

Digital transformation is fundamentally reshaping industries worldwide, moving beyond mere technological upgrades to encompass a holistic shift in how businesses operate, create value, and engage with their ecosystems. This profound evolution impacts everything from internal processes to external market interactions, driving a new era of efficiency, innovation, and strategic advantage. Understanding its multifaceted nature is crucial for any organization looking to thrive in the contemporary global economy, regardless of its specific industrial vertical.

Digital transformation is a comprehensive journey that integrates digital technology into all areas of a business, fundamentally changing how it operates and delivers value to customers. This paradigm shift is not just about adopting new tools; it’s about redefining business models, optimizing processes, and fostering a culture of continuous innovation. Across various industrial sectors, from manufacturing to logistics, this transformation is becoming a critical driver for sustainable growth and competitive differentiation in the global economy.

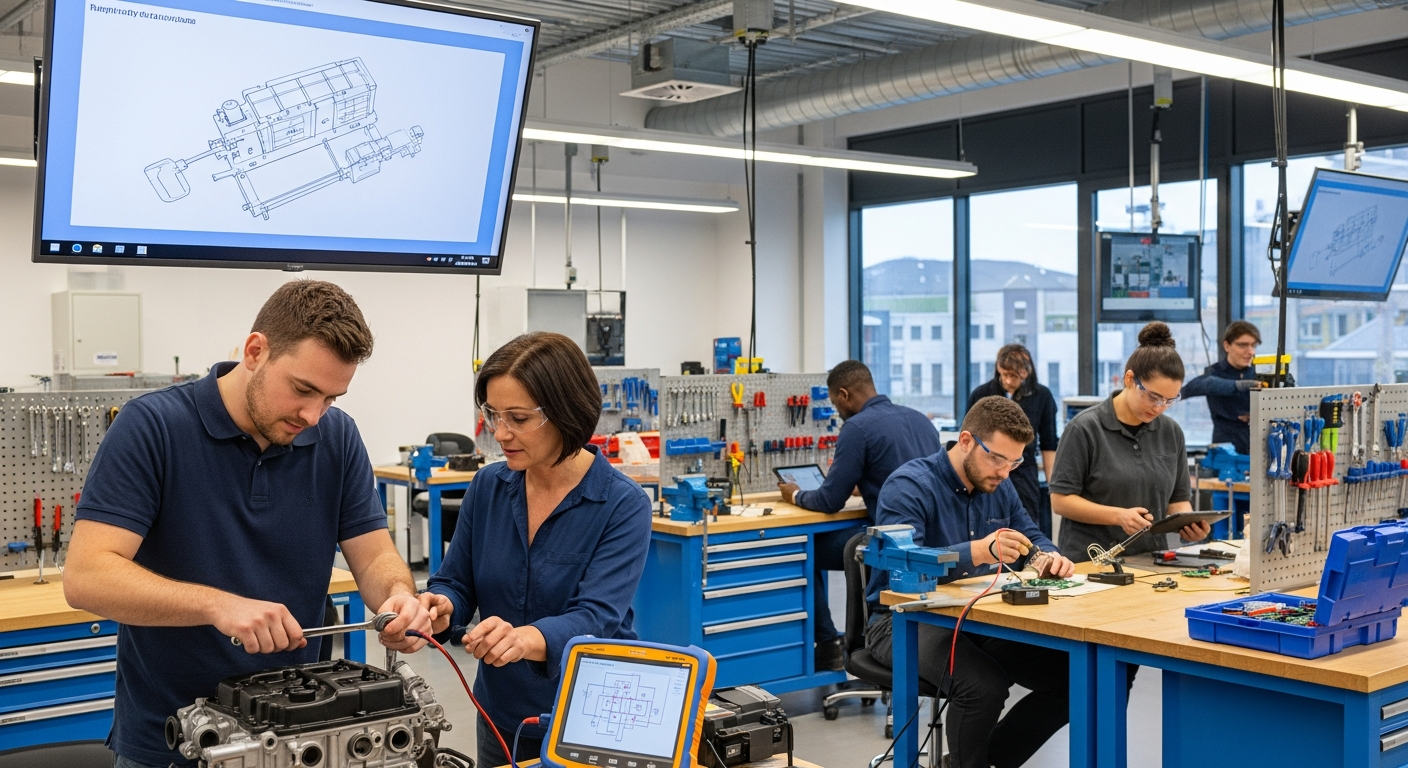

How Digitalization Reshapes Manufacturing and Production?

In the realm of manufacturing and production, digitalization is ushering in an era of unprecedented connectivity and intelligence. Concepts like Industry 4.0, smart factories, and the Industrial Internet of Things (IIoT) are becoming realities, enabling real-time data collection, advanced analytics, and predictive maintenance. This allows for more agile production lines, reduced downtime, and improved quality control. Automation and robotics play a pivotal role, optimizing repetitive tasks and enhancing precision, thereby boosting overall efficiency and output while contributing to a more sustainable production model through optimized resource use.

Enhancing Supply Chain and Logistics through Technology?

For supply chain and logistics operations, digital transformation offers significant opportunities to improve visibility, responsiveness, and resilience. Technologies such as AI, machine learning, blockchain, and advanced analytics are being deployed to optimize route planning, inventory management, and demand forecasting. This leads to more efficient movement of goods, reduced operational costs, and enhanced customer satisfaction. Real-time tracking and data-driven insights enable companies to identify and mitigate disruptions swiftly, fostering a more robust and adaptive supply chain that can navigate global market complexities.

Driving Efficiency and Innovation in Enterprise Operations?

Digitalization extends deeply into enterprise operations, streamlining internal processes and fostering a culture of innovation. The adoption of cloud computing, enterprise resource planning (ERP) systems, and customer relationship management (CRM) platforms centralizes data and improves cross-departmental collaboration. This integration allows for more informed decision-making, greater operational efficiency, and a clearer understanding of market dynamics. By automating routine tasks and providing employees with advanced digital tools, businesses can free up resources to focus on strategic development and creative problem-solving.

Strategic Approaches to Digital Transformation for Growth?

Developing a clear strategy is paramount for successful digital transformation. It involves identifying specific business challenges, setting measurable goals, and aligning technological investments with overall business objectives. Companies must consider their unique position in their respective markets and tailor their approach to leverage digital tools for sustained growth. This often includes fostering a culture of continuous learning, investing in workforce development, and exploring new commerce channels to expand their reach and adapt to evolving consumer expectations and the broader global economy.

The Role of Automation and Robotics in Industrial Advancement?

Automation and robotics are central pillars of industrial advancement within digital transformation. In manufacturing, robotic arms perform intricate assembly tasks with high precision, while autonomous guided vehicles (AGVs) streamline material handling in warehouses. Beyond physical robots, process automation, often powered by AI, handles administrative and data-intensive tasks, reducing human error and increasing throughput. These technologies not only enhance production capabilities and efficiency but also improve workplace safety by taking over hazardous or repetitive roles, contributing to a more advanced and sustainable industry.

| Service Category | Provider Examples | Cost Estimation (USD) |

|---|---|---|

| Cloud Infrastructure & Services | Amazon Web Services (AWS), Microsoft Azure, Google Cloud | $500 - $10,000+ per month |

| ERP System Implementation | SAP, Oracle, Microsoft Dynamics | $50,000 - $5,000,000+ |

| Custom Software Development | Accenture, IBM, local development firms | $20,000 - $500,000+ |

| Data Analytics & AI Solutions | Palantir, SAS, specialized AI consultancies | $10,000 - $1,000,000+ per project |

| IoT Device & Platform Integration | Siemens, GE Digital, Cisco | $5,000 - $250,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Digital transformation is not a one-time project but an ongoing journey that requires continuous adaptation and investment. It involves careful planning, significant resource allocation, and a clear understanding of the potential return on investment. The costs associated with digital transformation can vary widely based on the scale of the project, the complexity of the existing infrastructure, and the specific technologies being implemented. It often encompasses expenses for software licenses, hardware upgrades, cloud services, data migration, cybersecurity measures, and crucially, workforce training and change management to ensure successful adoption. Businesses should consider both initial outlay and ongoing operational expenditures when budgeting for their digital initiatives, recognizing that these are strategic investments aimed at long-term efficiency, growth, and market competitiveness.

In conclusion, digital transformation is an imperative for industries seeking to remain competitive and relevant in the modern global landscape. By strategically integrating advanced technologies into manufacturing, supply chain, enterprise operations, and overall business strategy, organizations can unlock new levels of efficiency, foster innovation, and achieve sustainable growth. It represents a fundamental evolution in how businesses function, demanding a forward-thinking approach to technology adoption and organizational development to thrive in an increasingly interconnected world.