Leveraging Additive Manufacturing for Mass Customization

Customization at scale: the holy grail of modern manufacturing. As consumer demands shift towards personalized products, businesses are seeking innovative ways to deliver unique offerings without sacrificing efficiency. Enter additive manufacturing, a groundbreaking approach that's revolutionizing production processes and enabling mass customization like never before.

The Evolution of Additive Manufacturing

Additive manufacturing has its roots in the development of stereolithography by Chuck Hull in 1986. This process involved using ultraviolet light to cure and solidify thin layers of photopolymer resin, building up a three-dimensional object layer by layer. Since then, numerous other additive manufacturing technologies have emerged, including fused deposition modeling (FDM), selective laser sintering (SLS), and metal powder bed fusion.

As these technologies have matured, their applications have expanded beyond prototyping. Today, additive manufacturing is used in industries ranging from aerospace and automotive to healthcare and consumer goods. The global market for 3D printing is expected to reach $34.8 billion by 2024, growing at a compound annual growth rate of 23.5%.

Mass Customization: A Paradigm Shift in Manufacturing

Mass customization represents a fundamental shift in the way products are designed, manufactured, and delivered to consumers. It combines the flexibility of custom-made products with the efficiency of mass production, allowing businesses to offer personalized goods at scale. This approach has become increasingly important as consumers seek unique products that reflect their individual preferences and needs.

Traditional manufacturing methods often struggle to accommodate mass customization due to the high costs associated with retooling and reconfiguring production lines. Additive manufacturing, however, offers a solution to this challenge by enabling on-demand production of customized parts without the need for expensive molds or tooling.

The Synergy of Additive Manufacturing and Mass Customization

Additive manufacturing is uniquely suited to support mass customization efforts for several reasons:

-

Design flexibility: 3D printing allows for the creation of complex geometries that would be difficult or impossible to produce using traditional manufacturing methods. This enables designers to create highly customized products without being constrained by the limitations of conventional tooling.

-

On-demand production: With additive manufacturing, businesses can produce items as they are ordered, eliminating the need for large inventories of standardized parts. This reduces waste and allows for greater responsiveness to customer demands.

-

Cost-effective low-volume production: Traditional manufacturing often requires high volumes to justify the costs of tooling and setup. Additive manufacturing, on the other hand, can be economically viable for small production runs, making it ideal for customized products.

-

Rapid iteration: The ability to quickly produce prototypes and test different designs allows for faster product development cycles and more responsive customization processes.

-

Material innovation: Advances in 3D printing materials have expanded the range of properties and finishes available, enabling greater customization options for end-use products.

Implementing Additive Manufacturing for Mass Customization

To successfully leverage additive manufacturing for mass customization, businesses should consider the following strategies:

-

Invest in the right technology: Choose additive manufacturing systems that align with your specific customization needs and production volumes. Consider factors such as build size, material compatibility, and production speed.

-

Develop a robust digital infrastructure: Implement advanced design software and product configurators that can seamlessly translate customer preferences into printable 3D models.

-

Optimize supply chains: Explore distributed manufacturing models that place 3D printing facilities closer to end-users, reducing shipping times and costs for customized products.

-

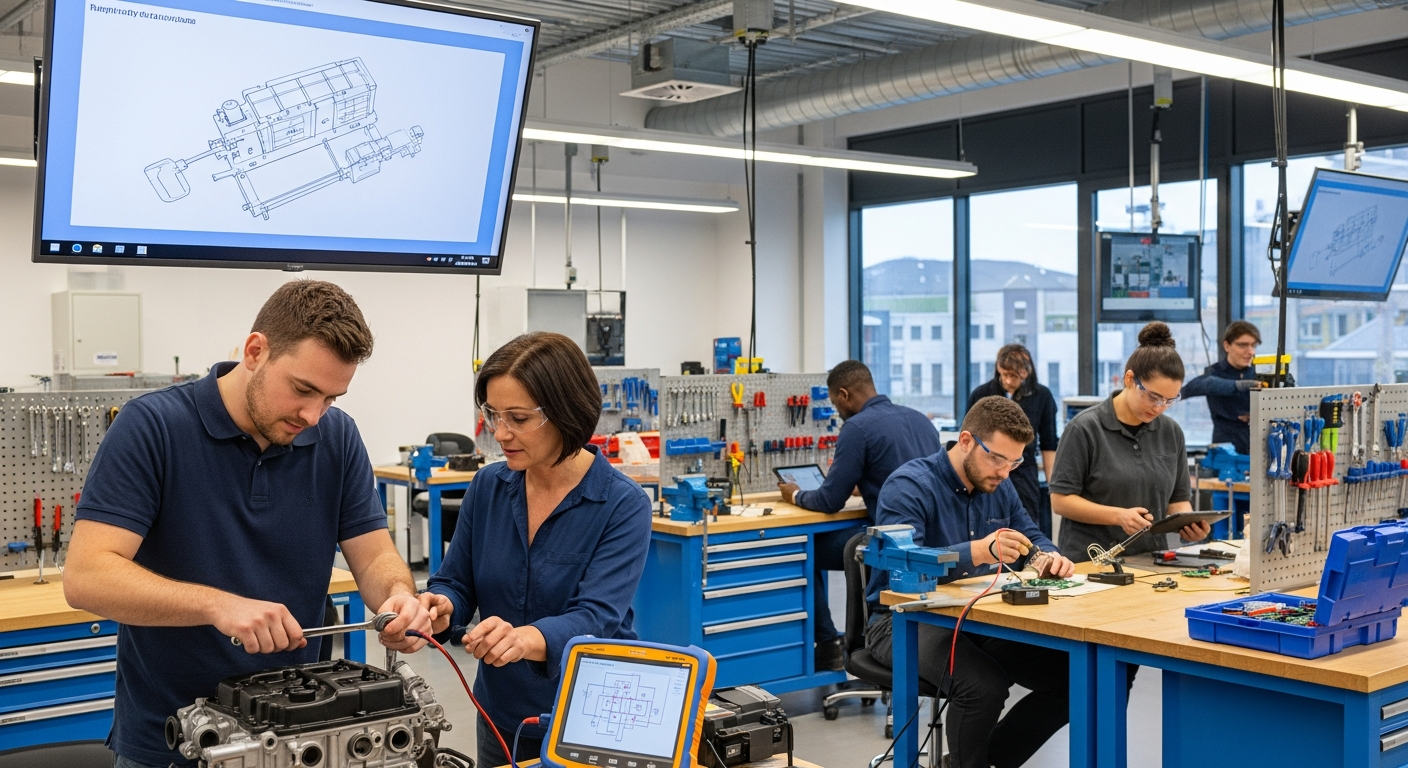

Train and upskill workforce: Invest in training programs to ensure your team has the necessary skills to design for additive manufacturing and operate 3D printing equipment effectively.

-

Collaborate with customers: Engage customers in the design process through co-creation platforms and feedback loops to ensure that customized products meet their expectations.

Challenges and Considerations

While additive manufacturing offers significant potential for mass customization, there are several challenges to consider:

-

Quality control: Ensuring consistent quality across customized products can be more challenging than with standardized mass-produced items.

-

Scalability: As demand for customized products grows, businesses must find ways to scale their additive manufacturing capabilities without compromising on quality or efficiency.

-

Material limitations: While the range of 3D printable materials continues to expand, there are still limitations compared to traditional manufacturing methods.

-

Post-processing requirements: Many 3D printed parts require additional finishing steps, which can add time and cost to the production process.

-

Intellectual property concerns: The ease of replicating 3D models raises questions about protecting designs and preventing unauthorized reproduction.

Key Strategies for Successful Implementation

• Conduct a thorough assessment of your product portfolio to identify items suitable for additive manufacturing and customization.

• Develop a user-friendly interface for customers to customize products within predefined parameters.

• Implement advanced analytics to predict demand patterns and optimize production scheduling.

• Establish partnerships with material suppliers and 3D printing service providers to access the latest technologies and expertise.

• Create a feedback loop with customers to continuously improve and refine customization options.

As businesses continue to explore the possibilities of mass customization, additive manufacturing stands out as a powerful enabler of this trend. By leveraging the unique capabilities of 3D printing technologies, companies can offer personalized products at scale, meeting the growing demand for individualized experiences. While challenges remain, the potential benefits of combining additive manufacturing with mass customization strategies are too significant to ignore. As the technology continues to advance, we can expect to see even more innovative applications that blur the lines between mass production and bespoke craftsmanship.